Vitamins:

- 3 * 1000mm 2060 aluminum exrtusion (misumi)

- 3 * 1500mm openrail v-rails

- 24 * T-nuts (included with openrail)

- 24 * M5 by 10mm button cap screws (included with openrail. Be sure to specify 10mm screws!)

- No new parts, Just the brackets from the triangle assembly.

Tools:

- 3mm ball-end hex key

- Rubber or wooden mallet

- Knife to clean parts

- M5 tap

- Tap your extrusions. This isn't necessary for this step, but it'll make adding feet much easier in the future. I tapped the center hole of each end of the long exstrusions for good measure.

- Cut the openrail in half. You should have 2 750mm sections.

- Pre-thread the T-nuts through the rails. I used every other hole.

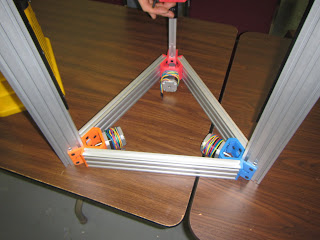

- Notice the v-sections interlocking.

4. Slide the v-rails into the 2060 aluminum. Lightly tighten a few bolts such that there's about 125mm gap at either end.

5. Clean up the brackets - make sure that both top and bottom of each bracket is free of lips/ridges that could catch on the extrusion.

6. Slide the rails into the idler triangle. Carefully align the t-nuts in the brackets, and tap home with the mallet. This step is tedious! Go slow and make sure all the t-nuts slide in.

7. When all three vertical beams are installed, repeat for the motor triangle. Be sure that your colors line up! Hint: You can flip the motor triangle to make the colors align. You can't flip the idlers, which is why we started up there :-)

8. Finally, loosen the rails and slide them tight against the idler brackets. There will be a gap above the motors.

9. Align the v-rails on the extrusion and tighten every screw.

|

| That's me! |

|

| Bertha Mark 4 next to Mark 3. 3 looks bigger, but the print area will be about the same. |

No comments:

Post a Comment